STT and Tokyo Electron to co-develop ST-MRAM manufacturing process

The combination of STT’s ST-MRAM technology and TEL’s PVD MRAM deposition tool will allow the companies to develop processes for ST-MRAM.

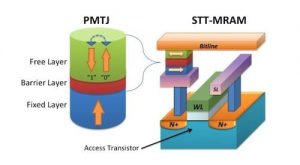

STT is contributing its perpendicular magnetic tunnel junction (pMTJ) design and device fabrication technology, and TEL is contributing its ST-MRAM deposition tool and knowledge of unique formation capabilities of magnetic films.

STT and TEL will demonstrate solutions that are far denser than other ST-MRAM solutions while eliminating barriers to replacing SRAM.

These sub-30nm pMTJ’s, 40 to 50 percent smaller than other commercial solutions, should be attractive to advanced logic–ICs and a significant step toward making DRAM-class ST-MRAM devices.

STT

“Industries have outgrown the capabilities of SRAM and DRAM leaving the market open for the next generation of technology,” says Tom Sparkman, CEO of STT, “having TEL, the world’s leading ST-MRAM deposition equipment supplier, as a partner speeds up the development of STT’s technology for replacing SRAM and DRAM. We believe the adoption of ST-MRAM will materially exceed current expectations, and we are excited to work with TEL to revolutionize the ST-MRAM market by achieving the speed, density and endurance the industry needs.”

Tokyo Electron

“Together with STT’s team of experts, device fabrication know-how and its on-site development fab, we expect to accelerate the development of high-performance, high-density MRAM devices for the SRAM market and ultimately the DRAM replacement market.” says TEL’s Yoichi Ishikawa.